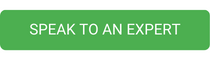

‘WMS, EDI & Sequencing Systems’ for Leadec Coventry Wheel & Tyre Assembly Plant

In March 2023, Infinity and Maxim collaborated on a Case Study with their client Leadec Coventry Wheel and Tyre Assembly Plant.

Infinity implemented a bespoke software system including WMS, EDI and Sequencing modules, which they support 24/7. Maxim continue to provide the essential hardware solutions and support that enable production to run efficiently.

We spoke to Nathan Read, who is the Plant Manager for Leadec’s Coventry Assembly Plant.

Could you introduce yourself and a bit about who Leadec are?

NR: ‘My name's Nathan Read; I'm the plant manager for Leadec Coventry Wheel and Tyre Assembly Plant. Leadec are a worldwide technical company that provide technical maintenance, and some assembly, for a lot of the OEM customers, food customers, technical manufacturing customers all around the world.’

Could you give us an idea of production before the initial WMS system came in?

NR: ‘Before we had the WMS, we produced wheels and tyres for a couple of smaller customers. Obviously our inventory exploded massively, along with the complexity. Leadec at the time had a very simple Excel based WMS system which didn't work very well with that amount of complexity. So we got Infinity involved to go through what we thought would be the best system for our type of business. There are some very unique parts we wanted in here that I haven't seen in other systems that Infinity were able to do for us.’

Since the initial WMS System, how has the software evolved?

NR: ‘We started off with a simple warehouse management system. We have a tracking system for all of our production lines. We have a notification system of any shortages, any issues we have. So, from anywhere in the world - basically on your mobile phone, you can see any buffers to any of our customers. I can see if there are any shortages on the lines and I can see how well every production line is doing.

Also, they've helped us with our quality side of it as well. So, the traceability data we have now and what we can see with the systems we put in for the sequencing has saved us no end of costs from our customers. We have a vision system that Infinity put in along with the sequencing that takes a photograph, every part that goes out of here. So, we can show that when the part left us, it was in a good state. So that's really helped us a lot.’

Could you take us through the Infinity/Mercia EDI* System?

NR: ‘Mercia handles all of our incoming EDI’s - EDM’s from our customer. It then translates all those for us and spits them out in a format that everyday Joe is able to understand. And from this, we have a complete bespoke planning screen. So, at any one time, we can move our stockholding up or down along with that and those can translate straight to the production lines. So, what it enables me to do is during times when they have issues, I can quickly reduce my stockholding at the click of a button. It will automatically work out what I need to build. If we do that with a human, it would take me a couple of days. We have complete traceability of every part that leaves this building, and there's no other system that I've used that will control your WMS and everything all the way through that does that. ‘

What are the benefits of the bespoke Sequencing System?

NR: ‘The sequencing system is we receive the sequence message from our customers that comes in the system automatically translate it. The guys will pick them. It's then checked again at the end of the line. During this process, at the very last step, a photograph is taken. That goes into a stillage that goes away to the customer. If they come back, have an issue, we can find that TLS, we can find that number, we can find the time it was built and sequence down the line. We can find everything all the way back to the day the tile was delivered from that system. For us, from a traceability point of view, that obviously saves us a hell of a lot of problems.’

How has your experience been with Infinity’s 24/7 Support?

NR: ‘We have a 24/7 support contract with Infinity because we're a 24 hour a day operation. The support with Infinity has been great; I think there aren’t many of the Infinity team I haven't spoken to at one point, at 1, 2 or 3 o’clock in the morning when issues have occurred. the support has been there from day one. I think the guys at Infiniti will tell you what started off as something quite small has ended up very, very big. And I don't think there's any one of our customers that hasn't been really happy with it. ‘

Could you talk to us about the hardware from Maxim; why you chose it and how it how it makes things easier for you?

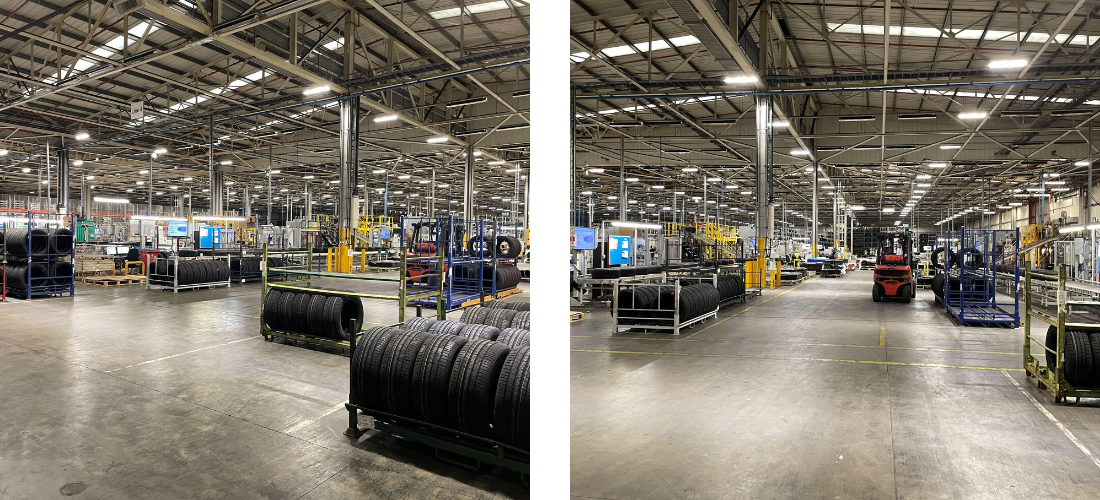

NR: ‘Because we wanted to make the system a bit more dynamic. When we first started the forklift truck drivers were able to put parts anywhere, and we didn't want that; We needed a dynamic put away system. So, the only way to do that was to give them facilities to be able to do that. I can pick a particular area of the warehouse and say that's for a high running part, a low running part, a medium running part. The system automatically will go and find and put them there as they're delivered, so that we're going less trips backwards and forwards to the line during the build process.

From the hardware side, whenever we've had issues, (Maxim) they've worked with us. Obviously, we started with different equipment. We thought we knew what we needed, we didn't listen to them. They told us what we needed, and it works really well now.

They're fantastic scanners, the long range scanners as well; We tried short range scanners, which didn't work very well where we had the labels on the floors and down by the sides getting damaged. But we have the labels for the warehouse about five, six metres up in the air where the forklift truck drivers can scan. So, these work absolutely fantastic. So, it works all the way through from the goods in right down to sequencing. So, any driver can do any role once they log in and they're given the access to do it. We can move a driver if we get busy from one area to another very, very quickly. Other systems didn't allow us to do that so easily.’

Would you recommend Infinity’s Software and Maxim’s Hardware services?

NR: ‘I would definitely recommend Infinity with the software side and Maxim with the hardware side. They've done a fantastic job for me. And, you know, I have spoken to other people who I deal with after 32 years in the automotive industry; this is probably one of the best way forwards I've ever seen.’

"This interview has been edited for length and clarity."